What are the empty aluminum tubes?

Empty aluminum tubes are a type of packaging commonly used for a variety of products such as cosmetics, pharmaceuticals, oil paints, food and adhesives. They are made of a thin layer of aluminum that is molded into a tube that can be folded up when the product is in use. The collapsible design helps prevent air from entering the tube and ensures that the product inside stays fresh for a longer period of time.

Collapsible aluminum tubes usually have a sealed opening on one end and a threaded cap on the other end that can be unscrewed and screwed on to dispense product. It is different from plastic tubes, aluminum laminated tubes, usually the end of the empty aluminum tubes produced from the factory is not sealed, and the mouth is covered with a cap, this is to allow customers to fill better, and customers do not need to waste too much time to screw on the cap causing more contamination.

These collapsible aluminum tubes can printed with product information, branding or other details, making them a popular choice for companies that want to promote their products. It allows customers to become familiar with the customer’s brand and product faster. Also, aluminum hoses are very textured and look upscale, making them perfect for some high-end products, especially cosmetics, oil paint brushes, food, etc.

Collapsible aluminum tubes have many benefits, including their lightweight and portable design, durability and ability to prevent product contamination. They are also recyclable and can be easily disposed of in a responsible manner, making them an eco-friendly packaging option. More and more customers are choosing to package their products in aluminum tubes.

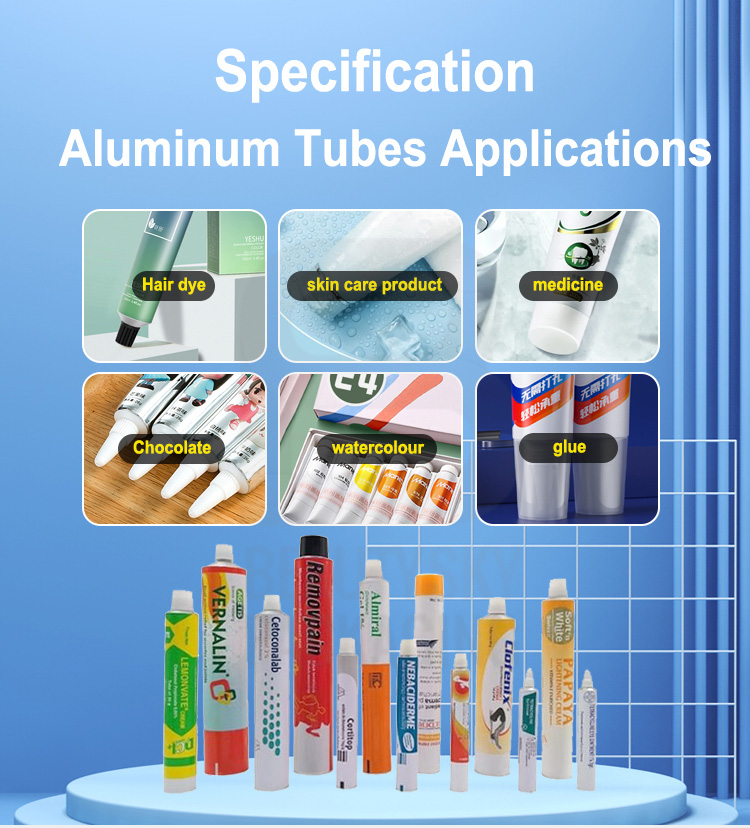

The popular usage of aluminum tubes

Aluminum collapsible tubes are used to package a wide range of products in various industries, including:

- Personal care: Toothpaste, hair dye, shaving cream, hair removal creams, sunscreen, and other beauty and personal care products.

- Pharmaceuticals: Ointments, creams, gels, and other topical medications.

- Food: Condiments, sauces, and other food products that require dispensing.

- Industrial: Adhesives, sealants, and other industrial products.

- Art: Oil paints, acrylic paints, and other art supplies.

- Miscellaneous: Some other products, such as shoe polish, lubricants, and insect repellents, also come in aluminum collapsible tubes.

Aluminum collapsible tubes are a popular choice for packaging because they are lightweight, easy to transport, and can be easily dispensed, making them suitable for a wide range of products. They are also durable and provide an excellent barrier against moisture, air, and light, which helps to preserve the quality of the products inside.

Aluminum collapsible tubes are a popular choice for packaging because they are lightweight, easy to transport, and can be easily dispensed, making them suitable for a wide range of products. They are also durable and provide an excellent barrier against moisture, air, and light, which helps to preserve the quality of the products inside.

Among the usage, there is a product that is very widely used. Many artists, art lovers are fond of making their own oil paintings at home and mixing their own colors, so they need to find a packaging material that can meet their needs, and aluminum tubes are a good choice for them. Empty aluminum paint tubes are from 5ml to 200ml according to customers’ requirements, especially 30ml empty aluminum paint tube is the most popular. This way they can put their own paint colors or mixed paint colors fill into the aluminum tubes by tube filling machine or by hand for storage, and they sealed soft tubes with a paint tube crimper, and the hermeticity of the tubes ensures that the oil paint will not deteriorate and they do not have to re-mix the colors next time.

The same for some smaller cosmetic companies, they can’t buy much quantity to fufill supplier’s MOQ. As a 100% enviroment packaging container, aluminum tubes are best choice for cosmetics. They can buy empty aluminum tubes packaging for their cosmetic creams and lotions, they can put labels on white or aluminum plain tubes.

But there is a question, how to seal the aluminum tube for personal use? They don’t have a machine or it isn’t cost-efficient to ask suppliers to do the filling process.

How do seal the empty aluminum tubes?

As metal tubes, they can’t be sealed easily. although they are soft and squeezed after annealing. Many people didn’t use aluminum collapsible tubes before, they don’t know how to seal the tube, how can they use empty paint tubes to hold their paints easily?

Sealing an empty aluminum tube can be done using a few different methods, depending on the tools and materials you have available. Here are some common methods for sealing aluminum tubes:

Heat sealing: This method involves using heat to melt the opening of the tube and seal it shut. To do this, you will need a heat sealer or a heating tool, such as a soldering iron or a heat gun. Simply place the opening of the tube onto the heated surface and apply pressure until it seals shut. Be careful not to apply too much heat, as this could damage the tube or cause it to burst.

Crimping: This method involves using a tool to crimp the opening of the tube shut. To do this, you will need a crimping tool, which can be purchased at most hardware or craft stores. Simply place the opening of the tube into the crimping tool and squeeze the handles together until the opening is sealed shut. It is the most popular solution for personal use.

Epoxy or glue: This method involves using an adhesive to seal the opening of the tube. To do this, you will need a strong adhesive, such as epoxy or superglue. Apply a small amount of the adhesive to the opening of the tube and press it closed. Hold the tube in place until the adhesive sets, which usually takes a few minutes. In squeezed aluminum tubes production, suppliers can put that epoxy latex at the end of tubes to help you seal tubes more easily.

No matter which method you choose, be sure to clean the opening of the tube before sealing it to ensure a secure seal. Additionally, be sure to follow any safety guidelines or instructions that come with the tools or materials you use.

You can find this sealing machine on the internet or contact us to purchasing for you.