As a widely embraced packaging material, aluminum collapsible tubes are increasingly prevalent in various industries, including pharmaceuticals, cosmetics, skincare products, adhesives chemical fields, and oil paints. Typically, these tubes are utilized for storing creams, ointments, paints, and other viscous substances.

Upon factory delivery, aluminum tubes come with their tips capped with different covers, ready to be filled from the opposite end. While this setup ensures the protection of the tubes during transportation and filling processes, it also presents a challenge: “How to effectively seal the tubes after filling?”

This concern is particularly common among clients, especially those new to utilizing collapsible aluminum tubes for packaging. For small or home-based businesses, finding professional filling services can be challenging, and investing in expensive sealing machinery is often impractical for low-volume orders.

The question then arises: “How do you seal aluminum tubes after filling?”

When customers fill skincare products such as hand cream, face cream, masks, or oil paints into aluminum tubes, it’s crucial to seal the tubes promptly to prevent contamination. While automated machines are available for sealing tubes immediately after filling (as demonstrated in this video: https://www.youtube.com/watch?v=-X9r2Kj76vc), their cost—ranging from several thousand to tens of thousands of dollars—makes them unfeasible for small-scale operations. It is obvious many clients can’t accept it.

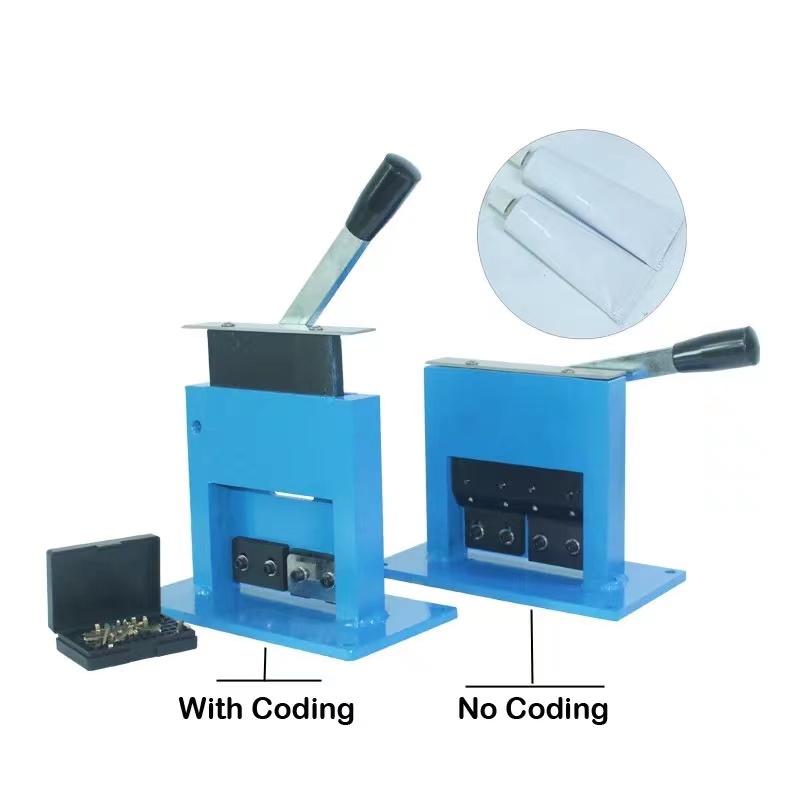

Fortunately, there is a cost-effective solution embraced by many customers: manual sealing devices. These handheld sealers, which typically cost less than $100 per unit, provide a practical and affordable alternative to expensive machinery. Users can easily seal aluminum flexible tubes by applying heat to the open end, ensuring a secure closure that maintains product integrity.

In conclusion, while automated sealing machines offer efficiency and convenience, they may not be financially viable for all businesses, especially those with limited budgets or production volumes. Manual sealing devices provide an accessible solution for sealing collapsible aluminum tubes after filling, enabling small businesses and artisans to maintain product quality without breaking the bank.

For further insights into the sealing process and to see the manual sealing device in action, refer to this informative video

If you are looking for empty aluminum paint tubes or aluminum cosmetic tubes, please contact Beauty Sky Packaging.