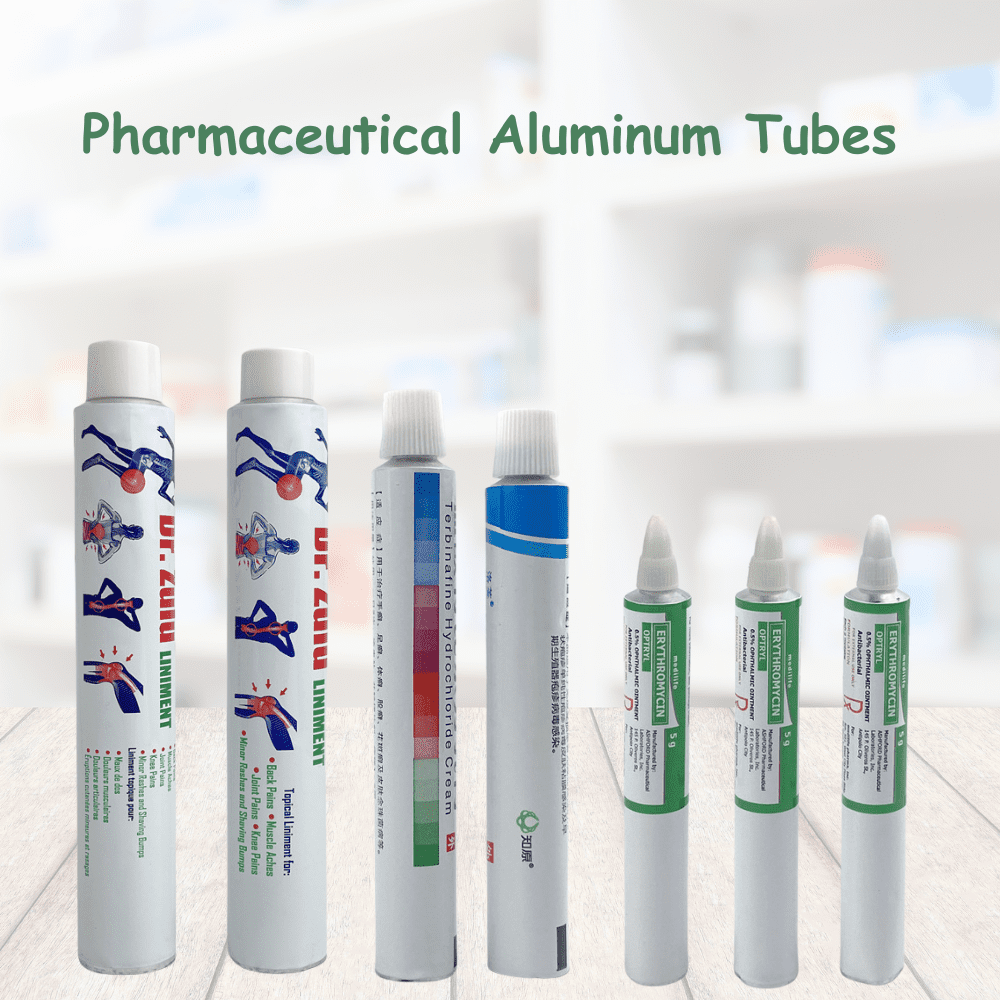

Pharmaceutical Collapsible Aluminium Tube

Aluminum tubes for Pharmaceutical ointment

10g–100g Are Available

Sealed Tip, Long nozzle, Plastic on-sert, Plastic nozzle Are Available

Pharmaceutical Cap Are Available

Different Nozzle Are Available, M7, M9, M11 are common

Golden Expoxy Resin Lacquer Is Available

Offset Printing Up To 6C

Silk Screen Printing, Hot Stamping Sticker On Collapsible Tube

Glossy Printing, Matte Printing Are Available

Product Features:

Collapsible Aluminum tubes are mainly used for packaging creams, ointment, gel, such as eye ointment, burn cream, dermatitis and other skin ointments, which occupy a very, very important position.

Then why do ointments need to use aluminum tubes to package? What are the special advantages of using aluminum tubes to package ointments?

What are the pharmaceutical aluminum collapsible tubes?

Material: 99.7% pure Aluminum Material

Thread: M7/3.5, M9/5.5, M11/7

Nozzle: Metricseald, Plastic-On-Sert, Extended Nozzle, Extended Plastic, Plastic On-Sert

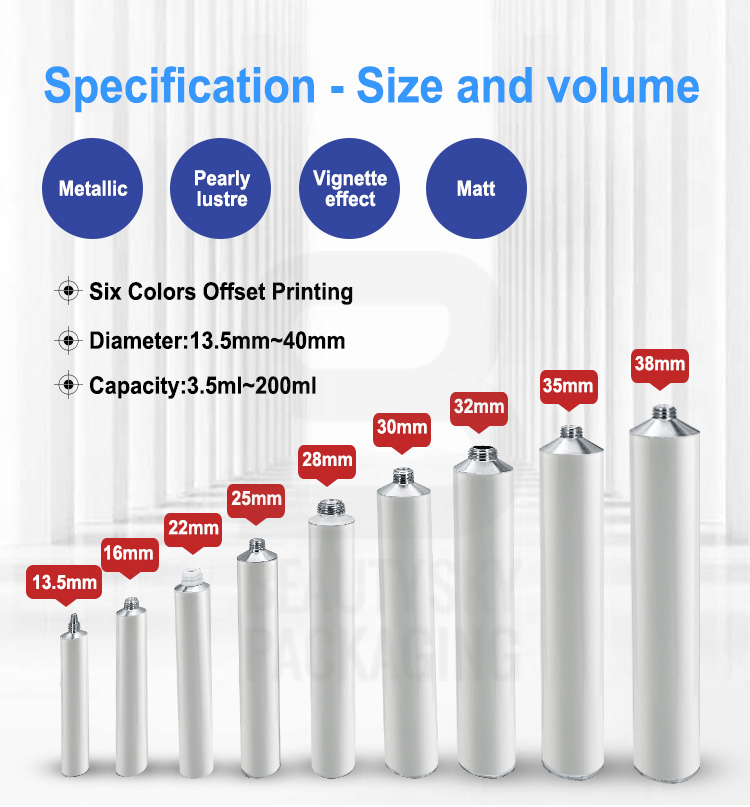

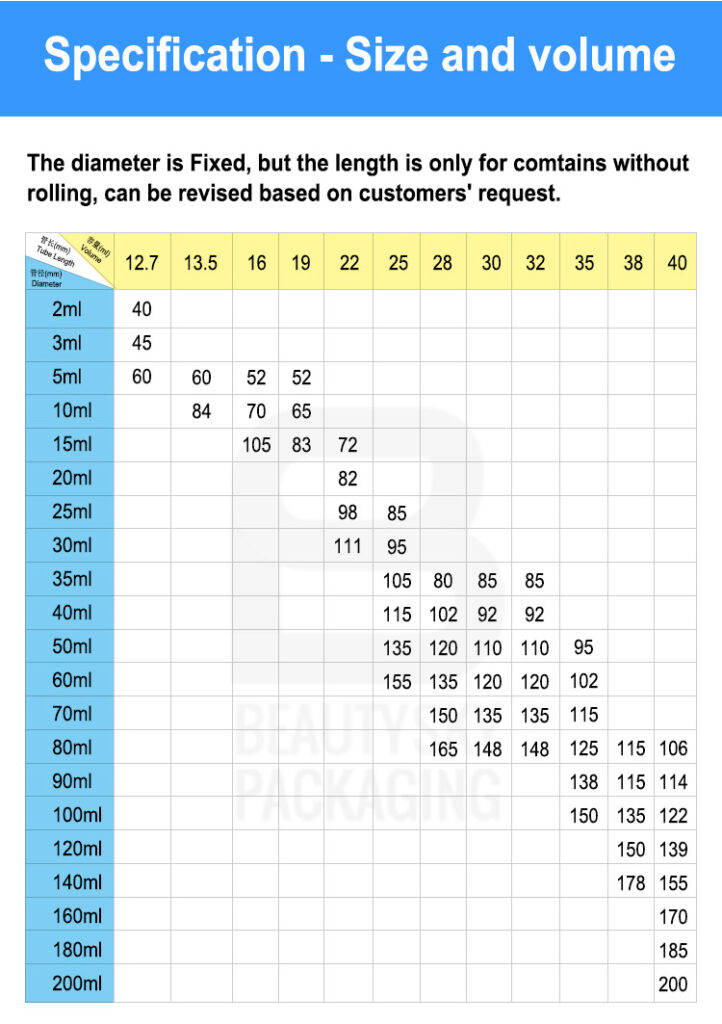

Capacity(ml): 3.5-200ml

Diameter(mm): 13.5mm,16mm,19mm,22mm,25mm,28mm,30mm,32mm,35mm,38mm, 40mm

Length (mm): 60-200mm

Thickness(mm): 0.1–0.16 Mm

Surface Finishing: 1-6color Offset Printing, White Plain, Aluminum Oil Plain, Glossy Or Matte Printed

MOQ: 20,000–100,000 PCS

Usage: Cosmetics, Hair Dyes, Skin-Care, Hand Cream, Facial Cream, Mask, Personal Care, Toothpaste, Pharmaceutical Ointment, Gels, Glue, Adhesive, Food, Cream Ketchup, Chocolate, Watercolor, Oil Pigment….etc.

In the pharmaceutical industry, apart from the look of packaging containers, aluminum collapsible tubes have so many benefits that they offer both to the consumers and the manufacturers.

What are the advantages of the aluminum collapsible tube for pharmaceutical ointment?

There are many packaging containers in the pharmaceutical industry, why does ointment like to use aluminum collapsible tubes not plastic collapsible tubes?

The collapsible aluminum tube is a container that has been softened and used for packaging creams, ointments and other products, it is one of the most important pharmaceutical packaging containers. Aluminum collapsible tubes can be used as the first choice of pharmaceutical ointment packaging, which can not be separated from its own superiority.

As a packaging material and container in direct touch with drugs, its material must be safe and stable. Metal is stable, but aluminum is much more stable and safe. As a pharmaceutical packaging ointment, the quality safety of aluminum tubes, the use of performance, as well as its compatibility with the drug, has a very important impact on the quality of the drug itself.

There are too much advantage of aluminum tubes: Eco-friendly / 100% recyclable / Light weight / unbreakable / Non-reactive nature / Corrosion resistant / Longer shelf-life for products. It is much better than plastic tubes as it’s 100% recyclable.

BENEFITS OF ALUMINUM TUBE PACKAGING?

1. Recycled Infinitely

2. Product protection

3. Shipping

4. Customizing

5. Sizing

6. Applicators

7. Complete product use

8. Luxurious feeling

1 . Good processing performance, strong plasticity.

The density of pure aluminum is only 2.7 grams per cubic meter, is a light metal, can be used in a variety of casting methods processing, easy to shape. In making aluminum tubes, the aluminum manufacturing process is simple and easy and the production of finished products is not easy to break, can greatly reduce processing costs conducive to energy saving. Also, it can produce tubes of different sizes, diameters, and lengths, different shoulders, different nozzles.

2. Corrosion resistance, good sealing

Aluminum and its alloy surface, easy to generate a layer of dense oxide protective film, can effectively isolate water, oxygen, etc., to avoid corrosion of the product in the process of circulation and use. And with the end latex of the empty aluminum hose has good sealing characteristics and more adequate sealing protection for the drugs contained inside.

3. Good thermal conductivity and good ductility.

Aluminum is a good conductor of heat, its thermal conductivity is three times greater than iron, and its electrical conductivity is second only to copper, and silver, when the cream in the hot filling, more conducive to facilitating rapid cooling heat dissipation, effectively ensure the stability of the cream.

4. Good shading and reflectivity

The polished surface of aluminum reflects more than 80% of white light, the higher the purity the higher the reflectivity, especially for infrared, ultraviolet, thermal radiation and other good reflective properties, can be used for storage on a variety of occasions, saving more storage and circulation costs, suitable for long-term display of the counter, increasing the chance of product exposure.

5. Non-magnetic, impact does not produce sparks.

This feature brings great guarantee for safe production management, and also brings high security for market circulation.

6. High barrier performance.

Compared with other non-aluminum materials, aluminum has excellent moisture and gas barrier. Generally speaking, aluminum foil thickness greater than 0.01MM, has a good moisture barrier performance. Greater than 0.015MM has gas impermeability. The increase of thickness can effectively improve the barrier performance.

7. Good and clear printing

The smooth surface of the aluminum tube is ideal for offset printing, but not for screen printing, hot stamping, silver stamping and other printing methods. Offset printing is to put all the text artwork on one page and then print it on the aluminum tube, so the overall text is clear and easy to read, which is also very important for pharmaceuticals.

What’s the popular volume for pharmaceutical packaging aluminum tubes?

Any volume is fine, wide range. The collapsible tube is flexible and squeezed.

The most popular dimension for eye ointment tube is 13.5mm, like 13.5mm for 5g

Also, 16*100mm for 10g, 19*105mm for 15g, 22*110mm for 20g, 22*130mm for 30g, 25*115mm for 30g, 25*145mm for 50g, 32*175mm for 100g.

What’s the printing for the aluminum medical tube?

There are offset printing, silver printing on aluminum tubes, with a glossy finish or matte finish. Also, the paper sticker applied on the flexible aluminum tube is a good method to expand clients’ brands & logos for some clients. Paper stickers can be hot stamping, silver stamping, glossy or matte.

What’s the quality problem may aluminum collapsible tubes have?

There Are Some Critical Defects:

Different Items Were Mixed;

Material Is Different From Specification;

No End Latex Application When Needed;

Printing With Text, Art Wrong Or Missing Or Displacement, Omit The Text;

The Low Resistance Of Paint In The Printing;

No Internal Coating Application;

Strange Particles Inside The Tube (Including Insect Or Metallic Particles

Tip Of Nozzle Can’t Be Pierced;

Aluminum Tubes Were Perforated Or Cracked;

There is an article dedicated to the quality of empty aluminum collapsible tubes that may be able to help you. Beauty SKy Group is an aluminum tube maker for 12 years, met most of the problems and solve them, we have the experience to avoid any problem. Now, we are the top 5 manufacturers in Pharmaceutical packaging tubes.

How do control the quality of aluminum squeeze tubes?

Beauty Sky Packaging is specialized in producing collapsible aluminum tubes for hair color cream, accounting for about half of the shipments. We have 12+ years of production experience, we had also had some quality problems in past years, although we had experienced workers. Failure is the mother of success, we will not make any mistakes from the failure lessons now. We use our past lessons to prevent any quality problems from occurring. You can trust us 100%!

Welcome your message anytime, best offer and free sample will be provided to you, also you may get a copy of aluminum tubes’ industry quality requirements to facilitate your understanding of our industry and to help you find the most suitable supplier.

How to test pharmaceutical aluminum tubes?

Pharmaceutical aluminum tubes are used to fill eye ointment and ointment drugs, which are in direct contact with eyes, skin, etc., so their safety and hygiene conditions must be viewed with high standards. In the whole production process, what are the quality testing items that must be paid special attention to? How should enterprises implement the quality inspection of ointment aluminum tubes?

The purity of the aluminum sheet: the purity of the aluminum sheet will affect the ductility and airtightness of the aluminum tube. The low purity of aluminum sheet represents more impurities in the aluminum sheet, which can easily lead to a decline in stretchability and is not conducive to stamping. Such a sheet of aluminum extruded by the punching machine, very easy to produce burrs or pits at the wall of the tube. After comparing the aluminum sheets of more than ten domestic and foreign aluminum sheet manufacturers, we finally choose the aluminum sheet with 99.7% purity, so that the aluminum sheet can meet the high-speed punching machine with strict requirements for precision, and the produced pharmaceutical aluminum hose has good ductility and strong air tightness.

Quality inspection of the inner coating: As the inner wall of the soft aluminum tube will be in direct contact with the ointment, in order to prevent the aluminum from contaminating the ointment or chemical properties of the strong ointment corrosion hose, must be coated with a protective film on the inner wall of the aluminum hose to isolate the two. Obviously, the quality of the inner coating of the soft aluminum tube will directly affect the isolation effect, such as the inner coating is not continuous, uneven, bubble, too thin, easy to fall off, the inner coating paint performance is not stable and the existence of these problems will bring great potential problems to the final product. The internal coating machine can apply three times to the inside of the aluminum hose, from the top of the tube, the shoulder, and the body to the end of the tube, to ensure the formation of uniform, continuous, thin and moderate thickness of the protective film. The inner coating paint of the pharmaceutical aluminum hose is made of FDA approved material, which has good leveling, stability and anti-aging properties to ensure the performance of the inner coating.

Test the continuity and chemical stability of the inner coating: The testing procedure of the quality of the inner coating is complicated, and professional instruments are needed to test the continuity and chemical stability of the inner coating. – Continuity of inner coating: below 20mA is regarded as qualified. Using the internal coating continuity tester, the coated aluminum hose is filled with the test solution of copper sulfate, a sliding electrode is immersed in the test solution, and the soft aluminum tube itself is in contact with a base electrode with a V-slot, then a DC voltage of 50.5V is applied between the sliding electrode and the aluminum tube, and the current flowed is proportional to the surface area of the aluminum collapsible tube not covered by the internal coating. If the coating is not continuous, there will also be black copper deposition phenomenon shows the location of leakage. The national standard stipulates that the leakage current shall not be greater than 40mA, the detection value is generally controlled at 20mA or less. – Chemical stability of the inner coating: cut the aluminum tube body longitudinally and level it, lightly rub the inner coating with skimmed cotton dipped in acetone 30 times, and observe whether the coating comes off on the skimmed cotton.

Flexibility and adhesion of the inner coating: The aluminum tube body is squeezed by the inner coating flexibility and adhesion test device and then stretched, the inner coating should not fall off.