What are the aluminum collapsible tubes?

The collapsible aluminum tube is the preferred packaging format mainly used for ointments and creams that require a high barrier property to achieve product stability over a long period of time, it is made from pure 99.7% aluminum, round, hollow cylinders shape, with aluminum body, shoulder, screw and plastic cap. The collapsible aluminum tubes are widely used worldwide for packaging pharmaceutical, healthcare, and food products. They are coated internally to provide stability; they serve as a means of protecting the contents of the tube from oxidation.

The demand and application of the collapsible aluminum tubes have greatly increased recently, and most of the world key marketers, with an inclusion of the pharmaceutical sector, have been laying demands and giving much preference to the collapsible aluminum tubes as a result of the huge benefits they render

Collapsible aluminum tubes are made of 3 parts: the main part, a shoulder to one end of which a screened nozzle is fixed, and a molded cap that closes the orifice. Collapsible tube were designed initially for packing artists oil. However, we can see that its uses have greatly exceeded that of a wide range of products especially cosmetic creams, hair coloring cream, hand cream, mask, watercolor, shaving cream, toothpaste.

We can also see that the use of aluminum tubes has greatly replaced the use of plastic tubes nowadays, these tubes are in close proximity with our day to day lives, and we find their use in every aspect of our lives, for instance, one of the first things we make sure we do when we wake up is to brush our mouth and take our bathes, the toothpaste we make use of in brushing our tooth is stored or contained in a collapsible aluminum tube, apart from these so many things we make use of in our day to day activities are now stored in aluminum collapsible tubes because they are very portable are easy to carry about.

Collapsible tube is made up of many materials, including tin and lead. Most of these collapsible tubes are usually made of tin alloy or aluminum, mainly because they are used to hold or contain liquid or viscous products such as toothpaste.

The majority of the medical creams or ointments are marketed and sold in collapsible tube made from aluminum. As said earlier, collapsible tubes are made of tin alloy or aluminum, but it is very important to know that when it comes to the production of pharmaceutical products tubes, aluminum is mainly used.

The aluminum collapsible tubes are extremely important in the pharmaceutical industry; they are the best option for a semi-solid formulation that is very sensitive as a result of a minute degradation resulting from exposure to environmental stress. The aluminum collapsible tubes provide the best packaging for all semi-solids because it is not permeable to moisture, gas, odor, and light. It reduces the risks of air entering the pack and causing a reaction with the product.

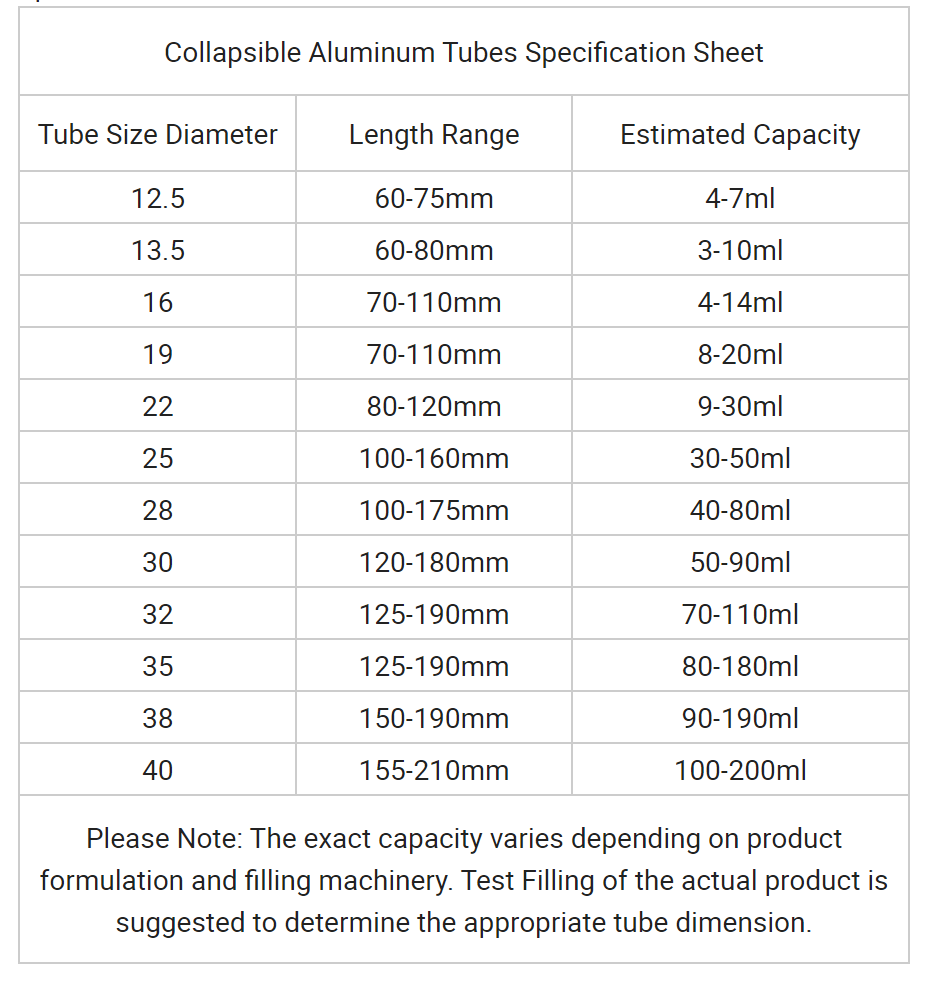

Collapsible aluminum tubes are basically one of the best collapsible materials readily available in different sizes. The collapsible aluminum tubes usually produce pharmaceutical drugs like oral health care products like toothpaste and skincare products. Offset printing helped aluminum tube to be excellent appearance. Below is dimension with volume from Beauty Sky Packaging (Shenzhen) Co., Ltd for choose.

The aluminum collapsible meet all the required and demanding standards for the packaging of most important and delicate products; it is very crucial for you to know that the closures and caps are a major part of the collapsible tubes; they help in ensuring that the tube will perfectly keep all the contents stored in the tube. Some of the areas where you can make use of collapsible aluminum tubes are listed below;

- Cosmetic products

- Ophthalmic products

- Adhesive products

- Haircare products

- Food items

- Adhesives

- Lubricants

- Veterinary creams and much more

As a result of the fact that the aluminum collapsible tube is produced in different sizes, they can perfectly meet all the requirements as demanded by various industries.

WHAT ARE THE ADVANTAGES OF USING COLLAPSIBLE ALUMINUM TUBE?

Collapsible aluminum tubes provide or offer a huge saving when it comes to shipping and transportation costs, resulting from their lightweight. There are so many advantages of making use of a collapsible aluminum tube, and we will be giving you a list of some of the advantages of making use of a collapsible aluminum tube below;

- They are extremely light in weight which reduces their transportation cost

- They provide the attractiveness of tin at a lower cost

- The aluminum surface reacts with atmospheric oxygen, which produces a tough coating of oxide which protects it from further oxidation

Using aluminum for the production of collapsible tubes has proven to be quite economical over the years, most of the creams and medical products we see all over the world are contained and stored in aluminum collapsible tubes.

HOW ARE COLLAPSIBLE ALUMINIUM TUBES MANUFACTURED?

Aluminum collapsible tubes are produced in the same process by which metallic collapsible tubes are also produced. The process by which collapsible aluminum tubes are produced is called the impact extrusion process; the impact extrusion process is a process that is used for the manufacturing and production of open-ended collapsible tubes from soft metals such as tin and lead.

When aluminum is being made use of in this process, it works hard at the forming process. This would require that the resultant tubes be annealed to regain their flexibility; in some cases, the aluminum tubes might not be annealed for them to be used as rigid containers.

The impact process is a process that is extremely useful in the production of extremely long containers. The extrusion process that is used in the production of metallic collapsible tubes is also similar to that of rigid aluminum containers, and the only difference is that the slugs that are used are rings instead of the disc and the female die, which is mainly used for holding the slug is shaped in a way such that the metal is forced to face downwards into the die with the sole aim of enabling it to form the shoulder and nozzle.

After this process, the tubes that have been formed are passed into a trimming machine where they are being cut into different shapes and lengths; after this, the tubes are moved to the next stage, which is the finishing operation stage, which includes the finishing operation of internal coatings, enameling, printing, and capping.

A rigid container can only be produced or gotten from aluminum, but when it comes to producing collapsible tubes, they can be as well gotten from softer metals such as tin, lead, and aluminum itself. Once the aluminum tubes have passed through the finishing stage, they must be well-annealed; this is mostly done to prevent them from being too springy and remove all traces of lubricants.

Out of the metals available, tin is the least reactive and very bright, but it is very expensive, and just like aluminum, it is also used in pharmaceuticals. The majority of the collapsible tubes are made from aluminum, mainly because they are very cheap compared to other collapsible materials; the major disadvantage in using aluminum is that they are subject to or prone to attack by some of the acidic or alkaline products.

The popular use of aluminum collapsible tubes is a result of the rapid development of the internal coatings systems, which are immediately sprayed into the tubes as they are formed. Some of the coatings materials used include; vinyl, epoxy, and phenolic resins, but the use of phenolic resins is restricted to aluminum tubes due to the high-temperature curing required.

WHAT ARE THE USES OF COATINGS FOR COLLAPSIBLE PACKAGING?

We cannot but overemphasize the importance of coating for collapsible packaging, and the collapsible packaging is usually coated on one or both sides. The inside coating is called internal coating or enamel, and the outside is called external coating or varnish. Some of the uses or benefits of coatings for collapsible packaging are listed below;

- They provide protection for the contents in the metal

- They serve as a means of protection of the tube from the contents of the tube

- They provide protection of the metal from the environment

- They aid or support decoration, labeling, and consumer information

- They serve as an influence for mobility or friction of the article during the filling operations

- They assist tooling for aluminum substrates

Coatings are applied to metals after the thermal treatment film on the metal; it is important to know that the coatings are often applied as wet film. Some of the major constituents and components in a coating are listed below;

- Resins

- Cross-linking agents

- Additives

- Solvents

WHAT ARE THE BENEFITS OF USING COLLAPSIBLE TUBES?

Using collapsible tubes provides its users certain benefits and privileges; some of these benefits are stated below;

- Tamper-proof:- The use of collapsible tubes make tampering impossible, and it cannot be refilled or reused

- Protective:- The contents in a collapsible tube are well protected and are free from all forms of contamination

- Hygienic: The collapsible tubes are hygienic and impart no taste, flavor, or odor to their contents.

- Lightweight; They are very light in weight and are very easy to handle or carry

The above are some of the major benefits of making use of collapsible tubes.

THE MARKET OUTLOOK OF COLLAPSIBLE ALUMINIUM TUBES

There is a huge expectation for the collapsible aluminum tubes to witness substantial and healthy growth in the next few years, resulting from the perpetual rising investment in innovation. One of the aluminum tube properties is that it possesses an extended shelf life and a very safe approach for administering a broad assortment of items.

The ability of the collapsible aluminum tubes is one of the major components that need to be specified, as it would greatly help in moving forward the development of aluminum tubes in the market.

The packaging of tubes is gaining a stable ground among the packaging manufacturers that cater to cosmetics and oral care applications. Aluminum materials possess certain qualities: lightweight, easy molding, anti-corrosive, and much more, which makes them a more preferred choice for packaging.

This has greatly served as a means of encouragement for manufacturers all over the world; most manufacturers are now opting for the use of aluminum collapsible tubes over other alternatives. It has been observed that one of the most economic benefits of using aluminum collapsible tubes is that they remain neutral or inactive when they are mixed with other products.

In addition to its effective material properties, aluminum collapsible tubes provide protection for a long period of time. The collapsible aluminum tubes have turned out to be one of the most innovative packaging products that are being offered in the global market for aluminum tubes.

Presently, the aluminum tube packaging market size Is estimated to grow and increase from 6.65 billion USD in 2016 to 9.30 billion in 2021 at a CAGR of about 6.9 percent. The global tube market can be said to be broadly classified into various segments, which are based on materials, applications, geography, and products.

The market can be segmented into laminated tubes, aluminum collapsible tubes, plastic tubes, and much more through material segmentation. We can say that they are classified or segmented into squeeze tubes, twist tubes, and much more in terms of the product type. The high demand for portable and convenient markets might lead to a major increase in the demand for squeeze tubes amidst others. It has been observed that the global tube packaging market is enormous in Europe and North America due to the fact that their per capita income and consumer spending is ever-increasing

If you are looking for reliable supplier of aluminum collapsible tubes from China, please take in account one factory which have been specialized in packaging aluminum tubes for 12 years till 2021. Get in touch with our customer support team, you will have special offers and free sample. Don’t wait, let’s talk today!